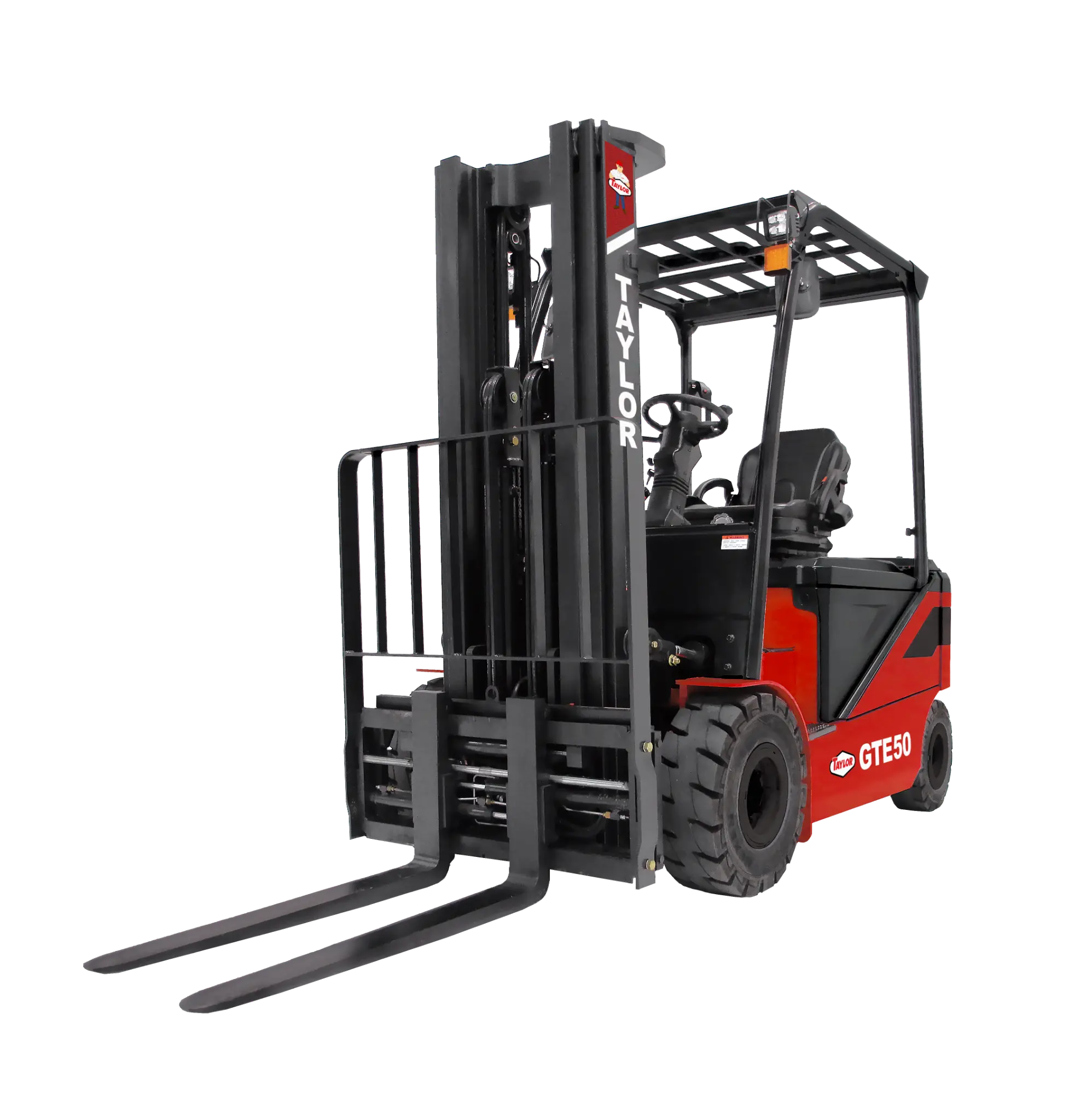

Taylor Inovation

Material handling solutions meeting the demands of the industry through battery-electric powered lift trucks and container handling equipment.

Battery-Electric Vehicles

FAQ

Let's see if we can help.

The charger may be scheduled for delivery prior to delivery of the Taylor truck. Input power requirements from the customer’s utility should be confirmed with the Taylor sales representative.

All chargers must be commissioned by the charger manufacturer at the customer site. The charger will not be operational until commissioning has been completed. The charger must be installed and wired according to the provided Installation Manuals prior to submitting the Charger Commission Request Form to Taylor.

Depending on each customer’s existing infrastructure, varying levels of site preparation/modifications may be required. The Charger Commission Request Form may be submitted a minimum of two (2) weeks prior to the requested commission date.

- **Duty cycle data originates from 10,000+ hours of full-production operations.

- ***ZH runtime does not require opportunity charging

- ****ZLC runtime observes lunch and two breaks (total 2hr downtime) but does not require opportunity charging.

The batteries used in Taylor forklifts and container handlers are manufactured by Proterra at their South Carolina facility.

These batteries are certified Made in the USA.

Contact your local Taylor Dealer or Factory Store.

California customers can also find information on the California CORE website.

Watch this video from the Port of Los Angeles

Ready to get started?

Contact us for more information about Taylor Battery-Electric material handling equipment.